FAQs

M.V. Blast Co. & Resurfacing

Have a sandblasting-related question? We have the answer. Check out these FAQs and give us a call today for more information!

-

What is sandblasting?

Sandblasting is a surface preparation technique that involves propelling abrasive materials (such as crushed recycled bottle glass) at high speeds to clean, roughen, or shape a surface. It's commonly used for cleaning, removing paint or rust, and preparing surfaces for painting or coating. M.V. Blast Co. & Resurfacing is happy to help you with your sandblasting needs.

-

What are the primary applications of sandblasting?

Sandblasting is used in various industries for tasks like removing old coatings from metal or wood, cleaning buildings, preparing surfaces for painting, etching glass, and creating textured or decorative finishes on various materials. M.V. Blast Co. & Resurfacing is a top local business in the sandblasting industry.

-

What abrasive materials are used in sandblasting?

While crushed, recycled bottle glass is a traditional abrasive, other materials like aluminum oxide, garnet, glass beads, and steel grit are also commonly used. The material used will depend on the desired finish and the surface being treated. M.V. Blast Co. & Resurfacing has a team of reputable sandblasters for all of your sandblasting needs.

-

How does sandblasting work?

Sandblasting involves a high-pressure system that propels abrasive particles through a nozzle at the target surface. The impact of these particles removes contaminants or creates the desired texture on the surface. M.V. Blast Co. & Resurfacing is the right company to call for your sandblasting needs.

-

Is sandblasting safe?

Sandblasting can be hazardous due to the generation of dust and the potential for injury if not used correctly. Proper safety equipment, including personal protective gear, must be used to minimize risks. Instead of doing this work yourself, please contact M.V. Blast Co. & Resurfacing today.

-

What safety precautions should be taken when sandblasting?

Safety measures include wearing protective clothing, eye and ear protection, respirators, and working in well-ventilated areas. It's also essential to follow safety guidelines for the specific type of abrasive and equipment used.

According to Zippia, there are currently more than 11,992 sandblasters working in the United States. M.V. Blast Co. & Resurfacing has a great team of sandblasters that people depend on. Call us today.

-

Can sandblasting damage surfaces?

If not used correctly, sandblasting can damage surfaces by removing more material than intended. The choice of abrasive and pressure levels must be carefully considered to avoid such damage. M.V. Blast Co. & Resurfacing is a team of sandblasters who will do a very professional job to ensure that your surfaces are protected.

-

What equipment is needed for sandblasting?

Sandblasting equipment typically includes a sandblaster unit, an abrasive storage tank, a nozzle, an air compressor, and safety gear like helmets, gloves, and respirators. Contact M.V. Blast Co. & Resurfacing to ensure that the proper equipment is being used in your home.

-

Are there environmental concerns with sandblasting?

Yes, sandblasting can produce dust and airborne contaminants, which can be environmentally harmful. It's crucial to use containment and dust collection systems and follow local environmental regulations. Our team at M.V. Blast Co. & Resurfacing knows what systems are necessary to keep people as safe as possible.

-

Can sandblasting be used on any surface?

Sandblasting can be used on many surfaces, but the appropriate abrasive and pressure levels must be chosen based on the material and the desired outcome. Delicate materials like glass may require lower pressure and finer abrasives. M.V. Blast Co. & Resurfacing understands what materials will help you reach your goals.

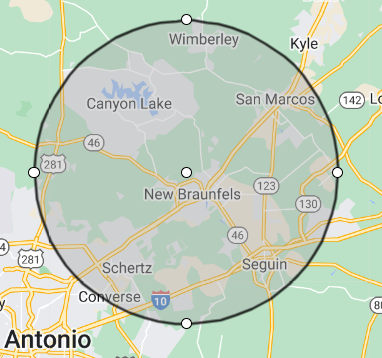

serving

New Braunfels, TX

San Antonio, TX

and surrounding areas

Business Hours

- Monday

- -

- Tuesday

- -

- Wednesday

- -

- Thursday

- -

- Friday

- -

- Saturday

- Closed

- Sunday

- Closed

Share On: